| |

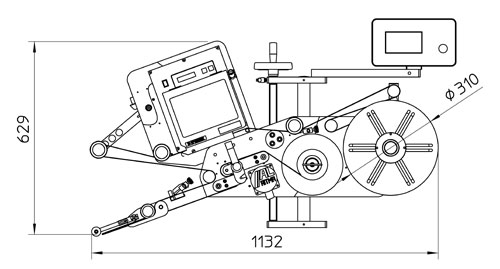

ALritma T – High performance, High speed print & apply

|

|

|

With a print speed of up to 16" per second, combined with a label application speed of up to 60m/min (40m/min standard), combined with the possibility of “ribbon saving”.

The key to the speed of ALritma T is its print unit control system, which uses a swinging arm to adapt the printer's operation to that of the label application on the basis of the loop of labels between the two different functions.

The unit is thus able to print and apply simultaneously and independently, and is at least twice as fast as any traditional real-time print-apply unit, like our ALcode.

ALritma T is also easy-to-use, as it is not limited to predetermined sizes for single labels, and does not require manual adjustment (for example when changing the label position). The unit is controlled by a powerful microprocessor equipped with a multilingual touchscreen, which provides the user with all the most common adjustments on a simple main screen. Once these adjustments have been entered, up to 40 formats (product/label combinations) can be stored, significantly simplifying and speeding up format changes.

ALritma T does not require compressed air and can operate, when necessary, as a normal stand-alone applicator: an extremely flexible tool, above all for the application of promotional labels, where sometimes a variable price is printed and applied, and other times only a preprinted label is applied.

The available functions and optional accessories are the same as for the ALritma label applicator.

Main Features

-

High-speed printing and delayed application: up to 300 labels/min - 40m/min

-

Independent label loop control arm provides the possibility to operate in application-only mode

-

Does not require the use of compressed air Extremely intuitive and easy-to-use

-

Incredibly flexible, allowing use of different size and shape labels: these can be used without having to change machine components.

Technical specifications ALritma T

|

Label width max mm. |

according to the printer |

|

Speed |

40 mt/min |

|

Controls |

Display touch screen |

|

Memory capacity |

40 formats |

|

Machine body protection |

according to the printer |

|

Unwind unit Ø |

300mm |

|

Standard alarms |

end of roll-web break-drag open |

|

Missing labels recovery |

current |

|

Near end of roll check |

optional |

|

Pneumatics applicators |

optional |

|

Encoder |

optional |

|

Transparent label sensor |

optional |

|

Coder / TT printer |

SATO module or compatibles |

|

AC Power |

240 V - 50 Hz - 400 W |

|

|

| |

|

|

|

« back

|

| |

|

|

| |

ALcode – Print and apply labelling machine for industry

|

|

|

For label printing, ALcode can be equipped with various thermal printer units from the Japanese manufacturer SATO (or compatible products).

These units have been developed specifically to be used on automatic applicators: print resolutions of 8 or 12 dots/mm and print speeds of up to 300mm/sec, available in 104 or 152 mm expandable print widths.

ALcode print-apply systems have been developed with a range of standard components which allow them to apply labels in any position and at virtually any line speed.

Available Versions

-

Air-blow applicator, with or without piston, for non-contact labelling of moving products

-

Tamp applicator for contact labelling of stationary products, including in recessed areas

-

Swinging roller applicator for contact labelling of products moving at high speed

-

Multi-format swinging-plate application system, for contact labelling of moving products, including those with different label sizes

-

Rotary arm applicator for front/back and/or corner labelling of both stationary and moving products.

Optional Accessories

The devices which may be added to the basic configuration of the Alcode label applicator in order to solve specific problems include:

-

Laser scanner to confirm label application

-

Product transport and transfer systems

-

Multiple labelling programs

-

Near end-of-roll monitoring

-

Oversized and powered unwind units.

Technical specifications ALcode

Set for being equipped with thermal SATO M series and S series print engines or comptible (Zebra Pax, Datamax, ACLASS, Cari Valentin).

Appicator :

|

Type |

Pneumatic |

|

Possible Configurations |

- Air-blow with or without piston

- Swinging roller

- with tamp for contact labelling

-

Rotary arm

- Multiformat swinging arm

|

|

Production Speed |

Up to 100 label/min depending on label size and on the applicator configuration |

Others:

|

Label roll diameter |

300 mm (option: 400 mm) |

|

Power supply |

220V, 50 Hz, 800W |

|

Pneumatic Feeding |

5 bars, 50 litre/min |

|

|

| |

|

|

| |

|

« back

|

|